info@apadanasolutions.com

Computational Fluid Dynamics Consulting Services

Cost-effective consulting services for your thermal-fluid engineering problems by world-class experts.

With over 15 years of experience in developing Computational Fluid Dynamics (CFD) models, we excel in solving real-world engineering problems. Our extensive experience enables us to recognize patterns in complex challenges. Our portfolio encompasses a wide range of industries, including aerospace, automotive, HVAC, and turbomachinery. By leveraging our simulations, we can significantly expedite your product development process.

Our Offerings

CAD and Mesh Generation

Meticulous preparation is essential in CAD and mesh generation to prevent potential issues during the solver stage. At Apadana Solutions, we prioritize the fine details of mesh generation, ensuring a robust solution downstream.

Solvers

Whether it involves an open-source software like OpenFOAM or proprietary suites like ANSYS or COMSOL, we possess the distinct capability to tailor the most cost-effective solver for your specific problem. Our expertise allows us to optimize the choice of solver to deliver efficient and customized solutions.

Post-Processing

Presentation matters, and here at Apadana Solutions, we strive for the harmonious blend of accuracy and artfulness when preparing the results, ensuring an impactful and visually appealing outcome.

Data Analysis

Data analysis forms the core of every successful CFD project. At Apadana Solutions, we offer an extensive array of statistical and mathematical analyses, enabling us to extract meaningful insights from your data. We are dedicated to providing comprehensive data interpretation to enhance the understanding of your project.

Recent Projects

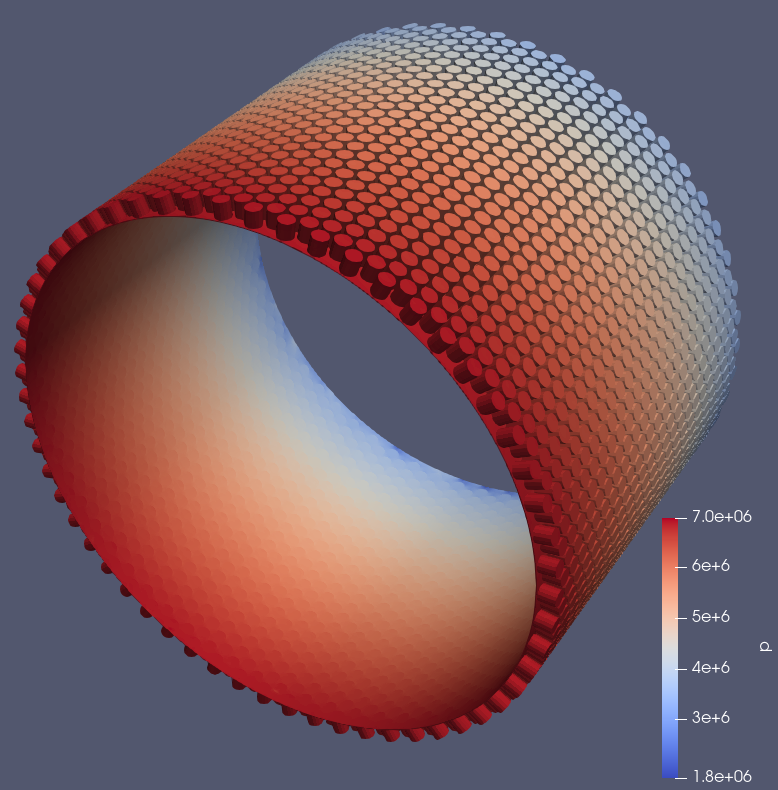

Turbomachinery Sealing

Seals play a critical role in ensuring the efficient operation of turbomachinery. Consequently, designers and operators are keen to understand the extent to which seals impact the distribution of forces on the rotating and stationary parts over time. CFD simulation offers a highly accurate and cost-efficient method for predicting rotordynamic forces, surpassing the limitations of traditional physical testing approaches.

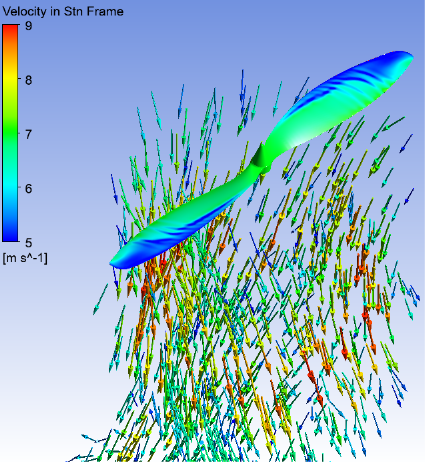

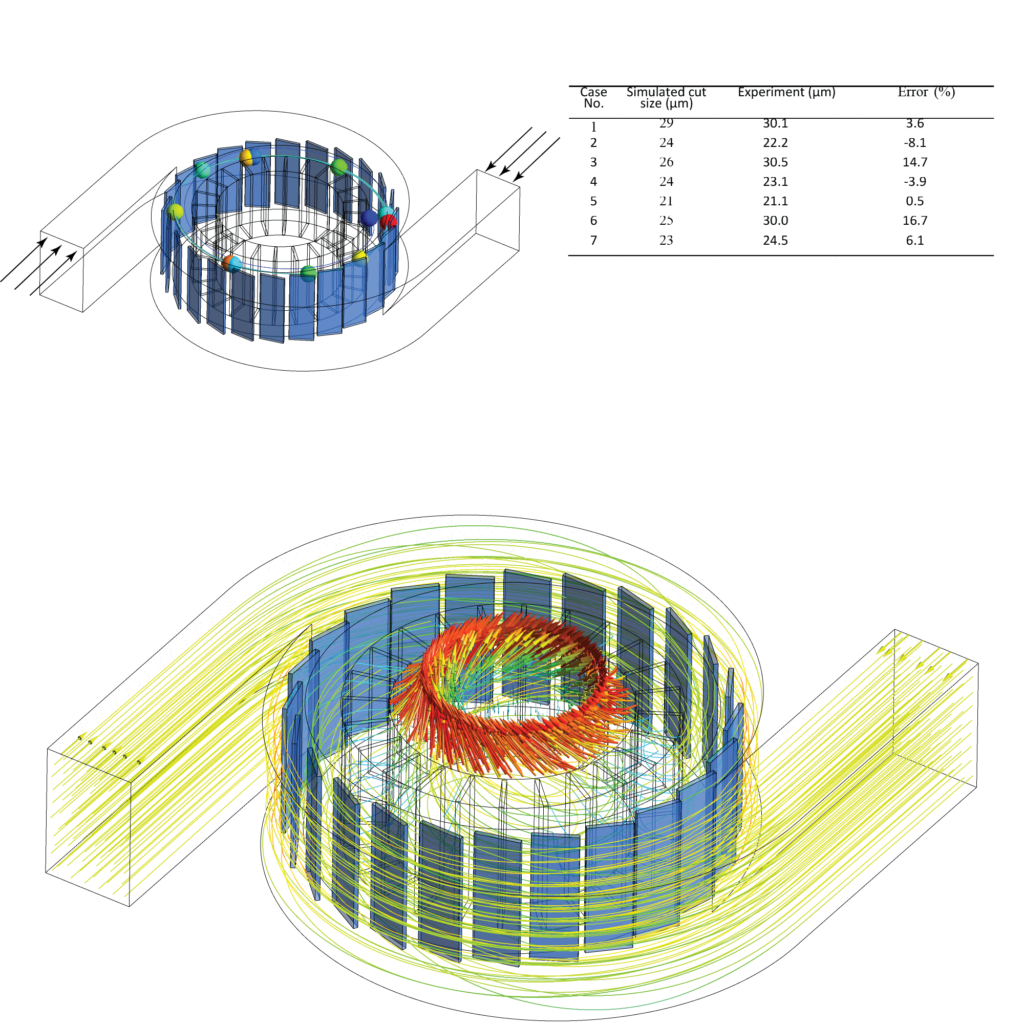

Turbo Air Classifiers

Classification devices are vital in various industries to isolate particles of specific sizes, including medicine, chemical production, metallurgy, and more. Turbo Air Classifiers are highly popular due to their excellent classification performance, adjustable cut size, and control over product granularity. Predicting the cut size is crucial for evaluating the classifier’s performance, and CFD is often used for accurate predictions due to limitations in theoretical/empirical methods.

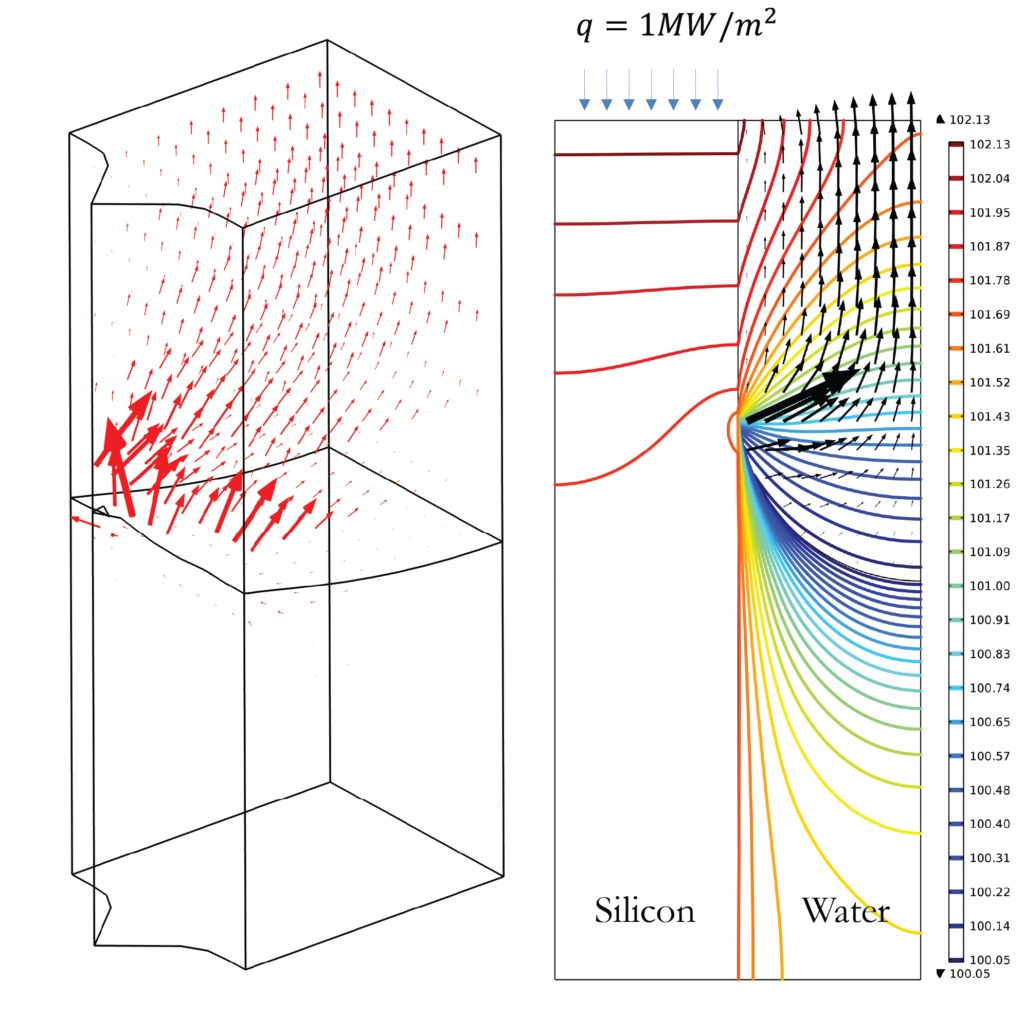

High-Flux Heat Dissipation

Efficient extraction and dissipation of high heat fluxes are vital for driving technological advancements in many industries, including computer chips and hypersonic flight. Two-phase flow cooling systems provide an effective solution for heat dissipation, capitalizing on the unique thermal characteristics of phase-change heat transfer. By leveraging CFD, the evaporation rate can be accurately predicted, enabling optimization of the design for maximum thermal efficiency even before physical testing is initiated.

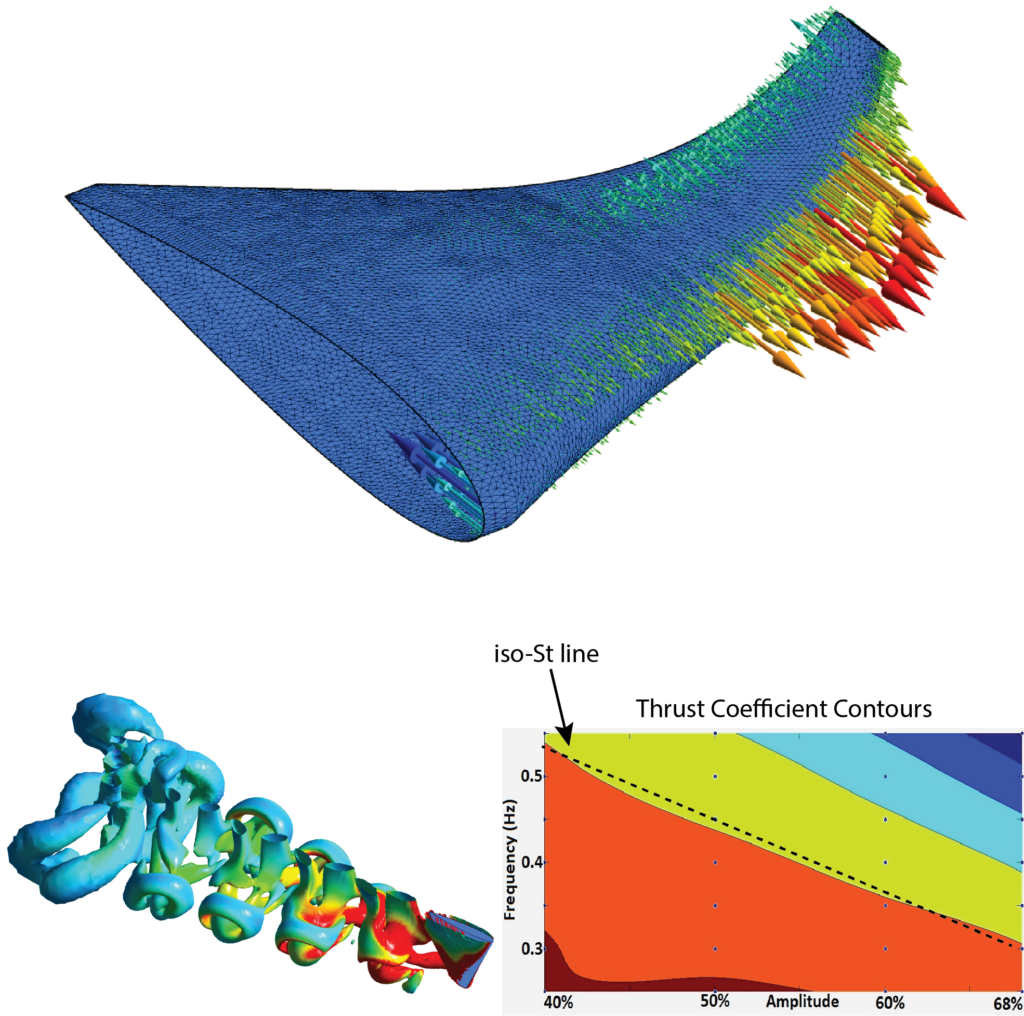

Fluid-Structure Interaction (FSI)

By considering the mutual influence of fluid forces and structural responses, FSI analysis plays a crucial role in improving product design across various industries. Leveraging CFD combined with Finite Element Analysis, designers can gain insights into complex fluid-structure interactions, assess structural integrity, identify potential failure modes, and refine product designs to enhance efficiency and durability. Whether applied to aircraft wing, offshore structures, wind turbines, or control valves, FSI analysis serves as a valuable tool in shaping robust and innovative solutions for enhanced product performance and reliability.

Team

Mehdi Saadat

Mehdi obtained his PhD in Mechanical and Aerospace Engineering from the University of Virginia. He later attended Harvard University for postdoctoral training. Through rigorous academic training, as well as external consulting for companies, he has amassed the necessary experience and knowledge to tackle and solve challenging industrial thermo-fluid problems.Throughout his tenure, he has published more than 30 publications and has been named an inventor on 1 United States patents, with over 400 citations. His work has received broad media coverage in National Geographic, Newsweek, New Scientist, Harvard Gazette among others. For a full list of publications please see here.